Unlocking the Secrets of High Purity Graphite: What You Need to Know

Jan 08,2026

Unlocking the Secrets of High Purity Graphite: What You Need to Know

Table of Contents

- 1. Introduction to High Purity Graphite

- 2. Unique Properties of High Purity Graphite

- 3. Production Methods of High Purity Graphite

- 4. Applications of High Purity Graphite in Various Industries

- 5. The Market for High Purity Graphite

- 6. Supply Chain and Global Trends

- 7. Future Trends and Innovations in High Purity Graphite

- 8. Frequently Asked Questions

- 9. Conclusion

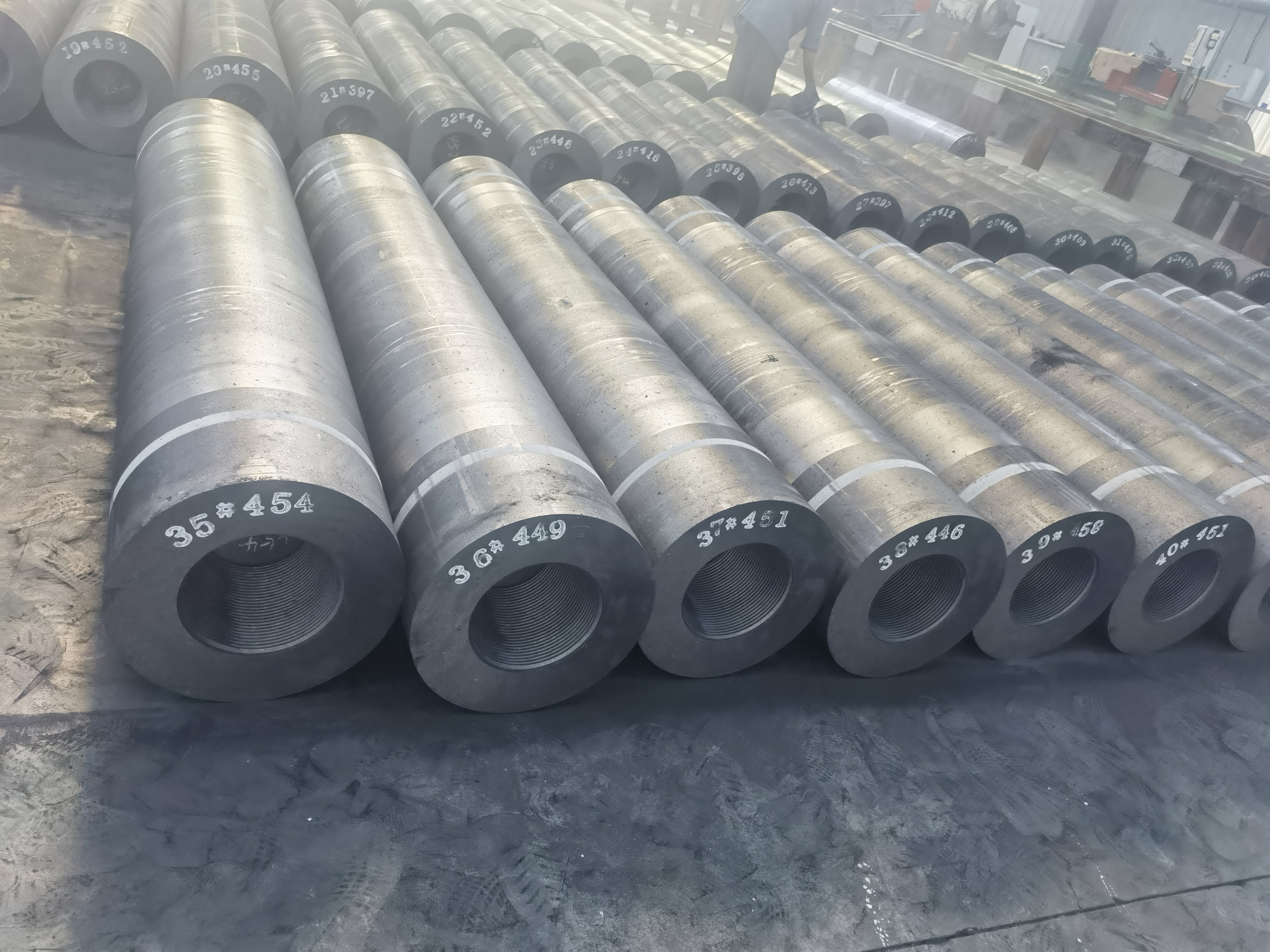

1. Introduction to High Purity Graphite

High purity graphite is a versatile and critical material that plays a pivotal role across numerous industries, including electronics, energy storage, and metallurgy. Characterized by its high degree of crystallinity and low levels of impurities, high purity graphite is essential for applications that require superior thermal and electrical conductivity. Understanding its unique characteristics and production methods can unlock opportunities for businesses and researchers alike.

2. Unique Properties of High Purity Graphite

The distinct properties of high purity graphite make it a prime candidate for various industrial applications.

2.1 Electrical Conductivity

High purity graphite exhibits excellent electrical conductivity, making it ideal for use in batteries and electrical components. Its ability to conduct electricity without significant resistance contributes to enhanced performance in electronic devices.

2.2 Thermal Conductivity

This form of graphite has remarkable thermal conductivity, which allows it to dissipate heat effectively. Its thermal stability enables it to withstand high temperatures without decomposing, making it invaluable in applications such as heat sinks and thermal management systems.

2.3 Chemical Resistance

High purity graphite is resistant to most acids and bases, offering durability in chemically corrosive environments. This property extends its usability in chemical processing and as a protective coating in various applications.

2.4 Lubrication Properties

Another intriguing aspect of high purity graphite is its lubrication capability. It provides a slippery surface that reduces friction, making it useful in applications requiring lubrication, such as in machinery and automotive components.

3. Production Methods of High Purity Graphite

The production process of high purity graphite involves several steps designed to remove impurities and enhance its desirable properties.

3.1 Mining and Sourcing

The journey of high purity graphite begins with mining. Natural graphite is extracted from deposits, typically found in metamorphic rocks. The quality of the raw material significantly influences the purity achieved in the final product.

3.2 Purification Techniques

To produce high purity graphite, various purification techniques are employed. These may include:

- Flotation: A common method where crushed ore is treated with chemicals to separate graphite from impurities.

- Acid Leaching: This process uses strong acids to dissolve impurities, resulting in a higher purity level.

- Thermal Treatment: High-temperature treatment further removes any remaining impurities and enhances the crystalline structure.

3.3 Final Processing

Once purified, the graphite undergoes final processing, which may include shaping, milling, and sometimes blending with other materials to meet specific application requirements.

4. Applications of High Purity Graphite in Various Industries

High purity graphite's unique properties make it indispensable in several sectors.

4.1 Electronics

In the electronics industry, high purity graphite is utilized in batteries, conductive coatings, and electronic components. Its exceptional conductivity ensures efficient energy transfer in devices such as smartphones, laptops, and electric vehicles.

4.2 Energy Storage

The rise of energy storage technologies, particularly lithium-ion batteries, has increased the demand for high purity graphite. It serves as an anode material, playing a crucial role in enhancing the battery's performance and longevity.

4.3 Metallurgy

In metallurgy, high purity graphite is used in the production of steel and other alloys. It acts as a lubricant during the manufacturing process and improves the quality of the final product by enhancing its properties.

4.4 Aerospace

The aerospace industry benefits from high purity graphite's lightweight and strength. It is used in components that require high thermal resistance and stability, such as rocket nozzles and heat shields.

4.5 Batteries and Fuel Cells

As renewable energy solutions gain traction, high purity graphite's role in batteries and fuel cells becomes increasingly significant. Its efficiency in energy storage systems is crucial for the advancement of sustainable technologies.

5. The Market for High Purity Graphite

The global market for high purity graphite is experiencing substantial growth, driven by increasing demand from various industries.

5.1 Market Trends

Recent trends indicate a shift towards sustainable and high-performance materials. Companies are investing in research and development to innovate new applications for high purity graphite.

5.2 Key Players

Several key players dominate the high purity graphite market, including both established corporations and emerging startups. These companies are focused on enhancing production methods and expanding their product offerings to cater to diverse industrial needs.

6. Supply Chain and Global Trends

Understanding the supply chain of high purity graphite is critical for industry stakeholders.

6.1 Sourcing Challenges

Sourcing high-quality graphite can be challenging due to geographical concentration in specific regions. Political and environmental factors can affect the availability and pricing of raw materials.

6.2 Global Trade Dynamics

The global trade of high purity graphite is influenced by demand from countries heavily investing in technology and energy sectors, such as the United States, China, and Europe. Monitoring these dynamics helps businesses strategize effectively.

7. Future Trends and Innovations in High Purity Graphite

As industries evolve, the future of high purity graphite looks promising.

7.1 Technological Advancements

Advancements in production technologies, such as new purification methods and innovative applications, are expected to enhance the quality and efficiency of high purity graphite.

7.2 Sustainability Initiatives

With a global emphasis on sustainability, efforts are being made to develop eco-friendly production methods. This includes recycling and repurposing graphite, which can significantly reduce environmental impact.

7.3 New Applications

The exploration of high purity graphite in emerging technologies, such as artificial intelligence, electric vehicles, and renewable energy sources, indicates a bright future with expanding possibilities.

8. Frequently Asked Questions

8.1 What is high purity graphite?

High purity graphite is a form of graphite that has undergone extensive purification to achieve a purity level of 99% or higher, making it suitable for various industrial applications.

8.2 What are the main uses of high purity graphite?

High purity graphite is used primarily in electronics, energy storage systems, metallurgy, aerospace applications, and as a lubricant in various industries.

8.3 How is high purity graphite produced?

High purity graphite is produced through a combination of mining, purification techniques such as flotation and acid leaching, and final processing steps to achieve the desired specifications.

8.4 What are the benefits of using high purity graphite?

Benefits of high purity graphite include excellent electrical and thermal conductivity, chemical resistance, and lubrication properties, making it versatile for many applications.

8.5 What is the future of high purity graphite in the market?

The future of high purity graphite appears promising, with increasing demand driven by technological advancements, sustainability initiatives, and new applications in emerging industries.

9. Conclusion

High purity graphite stands at the forefront of innovation and industrial advancements. Its unique properties, versatile applications, and growing market demand position it as a key player in the future of technology and energy solutions. By understanding its characteristics and production methods, businesses can effectively leverage high purity graphite to enhance their products and contribute to sustainable practices. As we continue to explore new frontiers in this field, the potential for high purity graphite remains vast and exciting.

Contact Us

E-mail:

Phone/WhatsApp:

+86 15711363051

Address:

Xingchuang International C912, Xinya Street No.15, Daxing District, Beijing, China