The Essential Role of Graphite Electrodes in Metallurgy and Energy Industries

Jan 09,2026

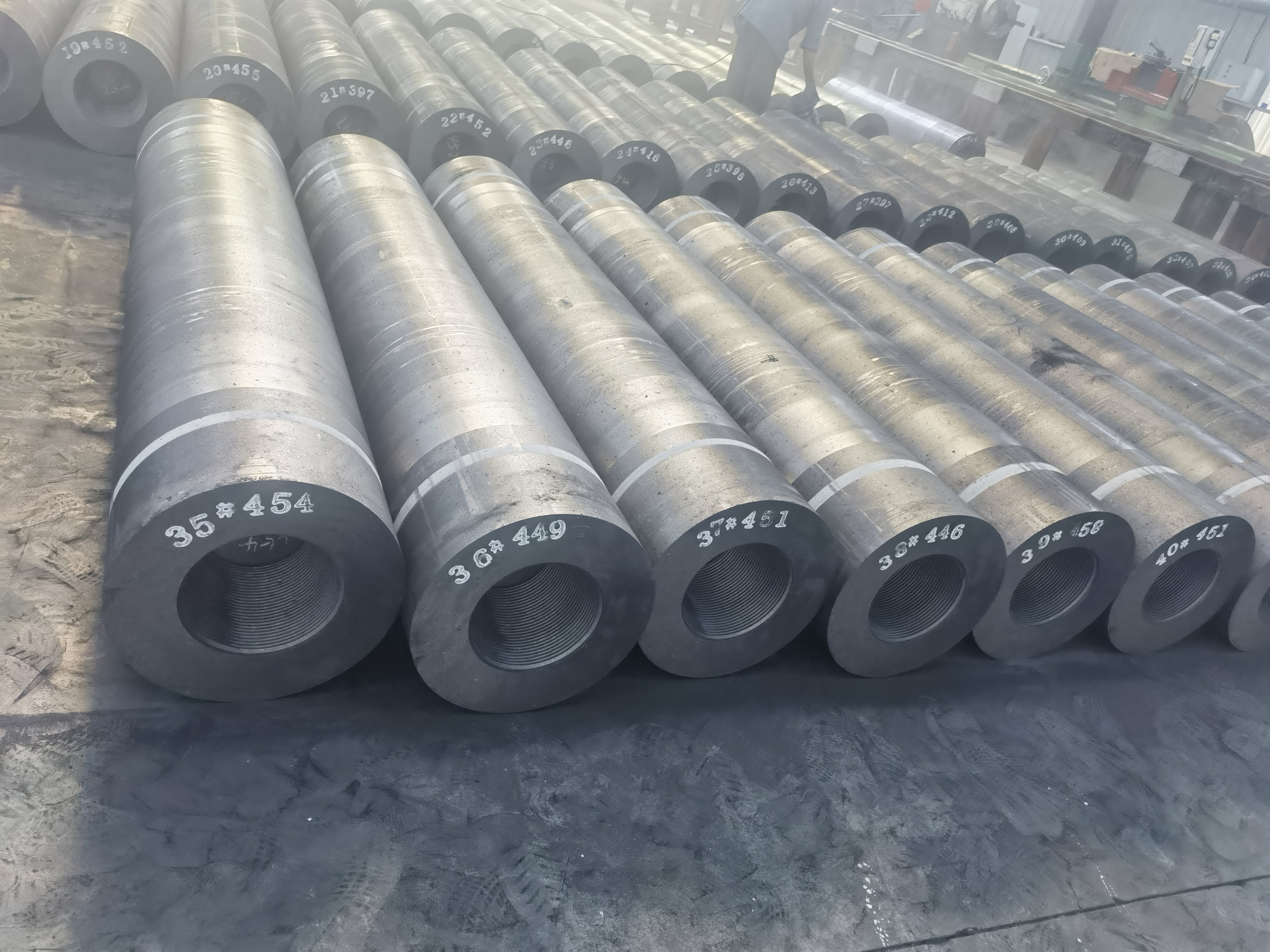

Graphite electrodes are pivotal components in the metallurgy and energy industries, particularly in the production of steel and other metals. Their unique properties, including high conductivity, resistance to thermal shock, and excellent mechanical strength, make them indispensable in electric arc furnaces (EAF) and other high-temperature applications.

In the electric arc furnace process, graphite electrodes serve as a conductor of electricity to melt scrap steel or other metallic materials. When an electric current passes through the electrodes, it generates heat, allowing for the efficient melting of raw materials. The ability of graphite to withstand high temperatures without deforming is crucial in this process, as temperatures in EAF can reach up to 1,800 degrees Celsius. Additionally, graphite electrodes exhibit superior resistance to oxidation, enhancing their longevity and reducing the frequency of replacements.

The production of graphite electrodes involves a series of processes, including the selection of high-quality petroleum needle coke, which is then calcined, crushed, and mixed with a binding agent. After forming, the mixture is baked at high temperatures to create a dense, durable product. This meticulous manufacturing process is critical, as the quality of graphite electrodes directly influences the efficiency and quality of the metallurgical processes they are designed to support.

Beyond metallurgy, graphite electrodes are increasingly finding applications in other sectors, such as renewable energy. In the development of batteries, particularly lithium-ion batteries, graphite is used as an anode material due to its ability to efficiently store and release energy. This application highlights the versatility of graphite beyond conventional uses, emphasizing its role in driving the transition to sustainable energy solutions.

Environmental considerations are also making their mark on the graphite electrode market. As industries strive to reduce carbon footprints, the shift towards electric arc furnaces, which utilize graphite electrodes, is gaining traction. These furnaces are generally more energy-efficient and produce fewer emissions compared to traditional blast furnaces. Therefore, investing in high-quality graphite electrodes not only enhances production efficiency but also aligns with global sustainability goals.

In conclusion, graphite electrodes are essential for modern metallurgical and energy processes. Their unique properties and adaptability to various applications make them invaluable in producing metals and supporting renewable energy advancements. As industries continue to evolve, the demand for high-performance graphite electrodes will likely increase, underscoring their importance in shaping the future of manufacturing and energy solutions. By understanding the vital role of graphite electrodes, professionals in the metallurgy and energy sectors can make informed decisions to enhance productivity and sustainability in their operations.

In the electric arc furnace process, graphite electrodes serve as a conductor of electricity to melt scrap steel or other metallic materials. When an electric current passes through the electrodes, it generates heat, allowing for the efficient melting of raw materials. The ability of graphite to withstand high temperatures without deforming is crucial in this process, as temperatures in EAF can reach up to 1,800 degrees Celsius. Additionally, graphite electrodes exhibit superior resistance to oxidation, enhancing their longevity and reducing the frequency of replacements.

The production of graphite electrodes involves a series of processes, including the selection of high-quality petroleum needle coke, which is then calcined, crushed, and mixed with a binding agent. After forming, the mixture is baked at high temperatures to create a dense, durable product. This meticulous manufacturing process is critical, as the quality of graphite electrodes directly influences the efficiency and quality of the metallurgical processes they are designed to support.

Beyond metallurgy, graphite electrodes are increasingly finding applications in other sectors, such as renewable energy. In the development of batteries, particularly lithium-ion batteries, graphite is used as an anode material due to its ability to efficiently store and release energy. This application highlights the versatility of graphite beyond conventional uses, emphasizing its role in driving the transition to sustainable energy solutions.

Environmental considerations are also making their mark on the graphite electrode market. As industries strive to reduce carbon footprints, the shift towards electric arc furnaces, which utilize graphite electrodes, is gaining traction. These furnaces are generally more energy-efficient and produce fewer emissions compared to traditional blast furnaces. Therefore, investing in high-quality graphite electrodes not only enhances production efficiency but also aligns with global sustainability goals.

In conclusion, graphite electrodes are essential for modern metallurgical and energy processes. Their unique properties and adaptability to various applications make them invaluable in producing metals and supporting renewable energy advancements. As industries continue to evolve, the demand for high-performance graphite electrodes will likely increase, underscoring their importance in shaping the future of manufacturing and energy solutions. By understanding the vital role of graphite electrodes, professionals in the metallurgy and energy sectors can make informed decisions to enhance productivity and sustainability in their operations.

Contact Us

E-mail:

Phone/WhatsApp:

+86 15711363051

Address:

Xingchuang International C912, Xinya Street No.15, Daxing District, Beijing, China