Why Choose Graphite Boats for Your Metallurgical Needs? Unveiling the Advantages and Applications

Jan 14,2026

Why Choose Graphite Boats for Your Metallurgical Needs?

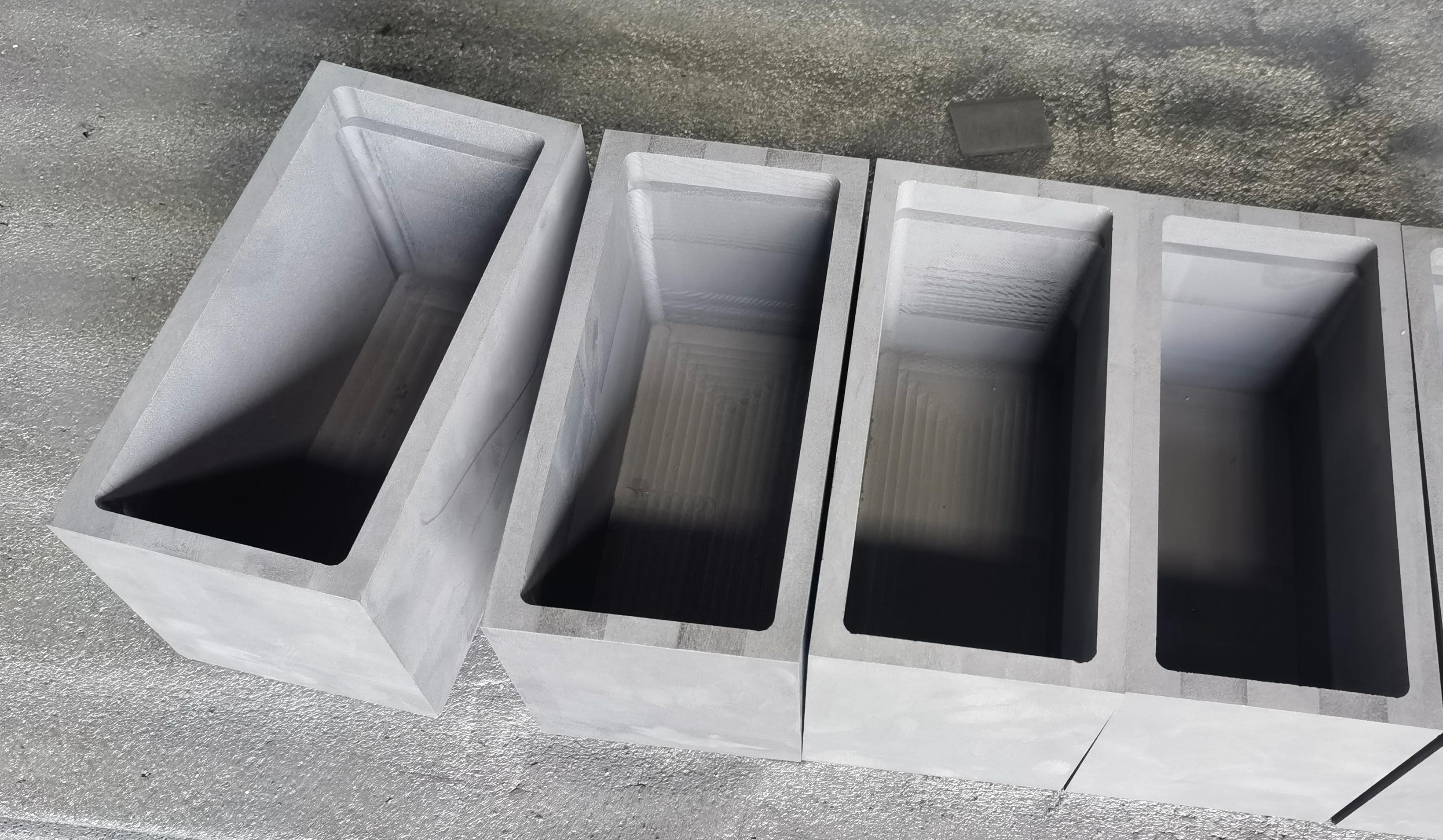

In the realm of metallurgical applications, the choice of materials plays a pivotal role in determining the efficiency, quality, and cost-effectiveness of processes. Among various options available, **graphite boats** have emerged as a preferred choice for many industries. This article explores the distinct advantages of graphite boats, their applications, and why they are an indispensable asset in metallurgical operations.

Understanding Graphite Boats in Metallurgy

Graphite boats are containers made from high-purity graphite, designed to hold molten metals and alloys during various metallurgical processes, such as casting and melting. They provide an excellent solution for industries needing to manage high temperatures and corrosive environments.

The Composition of Graphite Boats

The primary component of graphite boats is **graphite**, a form of carbon known for its remarkable thermal conductivity and resistance to thermal shock. These properties make graphite boats ideal for high-temperature applications, where other materials may fail.

Key Properties of Graphite Boats

1. **High Thermal Conductivity**: Graphite boats efficiently transfer heat, ensuring uniform heating of the contained material.

2. **Chemical Resistance**: They are resistant to many chemical reactions, making them suitable for various metallurgical processes.

3. **Low Thermal Expansion**: Graphite possesses minimal thermal expansion, which reduces the risk of warping or cracking under high temperatures.

4. **Lightweight**: Compared to metal alternatives, graphite boats are lightweight, making them easier to handle and transport.

5. **Reusability**: With proper care, graphite boats can be reused multiple times, offering significant cost savings.

Advantages of Using Graphite Boats

The benefits of incorporating graphite boats into metallurgical processes are substantial. Below, we outline the critical advantages that make them a superior choice.

Enhanced Efficiency and Performance

Graphite boats contribute to improved efficiency in metallurgical operations. Their ability to withstand high temperatures without losing integrity ensures that your processes run smoothly. This reliability translates to fewer interruptions and enhanced productivity.

Rapid Heating and Cooling Cycles

The high thermal conductivity of graphite allows for rapid heating and cooling cycles. This capability is essential in many metallurgical applications, where time is of the essence. Faster cycle times not only increase production rates but also improve the quality of the final product.

Cost-Effectiveness

While the initial investment in graphite boats may be higher than other materials, the long-term savings are undeniable. Their durability and reusability mean fewer replacements and reduced operational costs over time.

Reduced Maintenance Costs

With their resistance to wear and tear, graphite boats require less maintenance compared to other materials. This translates into lower costs associated with repairs and replacements.

Applications of Graphite Boats in Metallurgy

Graphite boats find applications across various metallurgical processes, demonstrating their versatility and effectiveness. Some of the prominent uses include:

Melting and Casting Operations

Graphite boats are widely used in melting and casting operations, where they hold the molten metal until it is ready to be poured into molds. Their ability to withstand extreme temperatures ensures that the metal remains in a liquid state without contaminating it.

Vacuum Induction Melting (VIM)

In vacuum induction melting, graphite boats are essential for maintaining a controlled environment. They prevent oxidation and contamination, ensuring high-quality melted products.

Metal Treatment Processes

Graphite boats are also utilized in heat treatment processes, where they facilitate the uniform distribution of heat. This uniformity is crucial for achieving desired material properties and structural integrity.

Non-Ferrous Metallurgy

Industries dealing with non-ferrous metallurgy, such as aluminum and copper, benefit significantly from the use of graphite boats. Their compatibility with various non-ferrous metals ensures efficient processing.

Why Graphite Boats Stand Out in the Industry

Several factors contribute to the growing popularity of graphite boats in metallurgical applications.

Innovation in Material Science

Advancements in material science have led to the development of high-purity graphite, enhancing the performance of graphite boats. These innovations ensure that they can meet the evolving demands of metallurgical processes.

Customization Options

Graphite boats can be customized to fit specific needs, including varying sizes and shapes. This adaptability allows industries to find solutions tailored to their unique requirements.

Environmental Considerations

With increasing awareness of environmental sustainability, the use of graphite boats aligns with eco-friendly practices. Their recyclability contributes to reduced waste, making them an environmentally sound choice.

Challenges and Mitigations

While graphite boats offer numerous advantages, there are challenges associated with their use.

Handling and Transportation

Graphite boats can be fragile, requiring careful handling. Industries often implement training programs for staff to mitigate risks associated with damage during transportation.

Initial Cost Barrier

The initial cost of graphite boats may deter some manufacturers. However, educating stakeholders about the long-term savings and efficiency gains can help overcome this barrier.

FAQs About Graphite Boats

1. What materials are graphite boats made from?

Graphite boats are primarily made from high-purity graphite, known for its thermal and chemical resistance.

2. Can graphite boats be reused?

Yes, with proper care and maintenance, graphite boats can be reused multiple times, making them a cost-effective solution.

3. What industries use graphite boats?

Graphite boats are used in various industries, including metallurgy, aerospace, and electronics.

4. How do graphite boats compare to metal alternatives?

Graphite boats are lighter, have better thermal conductivity, and are less prone to corrosion than many metal alternatives, making them advantageous in high-temperature applications.

5. What is the temperature tolerance of graphite boats?

Graphite boats can withstand temperatures exceeding 3000°F (approximately 1650°C) in inert atmospheres, making them suitable for high-temperature applications.

Conclusion

In summary, choosing graphite boats for your metallurgical needs offers numerous advantages, including enhanced efficiency, cost-effectiveness, and versatility in applications. Their unique properties make them an essential tool for industries dealing with high-temperature processes. As technology advances and the need for innovative solutions grows, graphite boats will continue to play a pivotal role in the metallurgical landscape. Investing in graphite boats not only enhances operational efficiency but also positions your business for long-term success in a competitive market.

Contact Us

E-mail:

Phone/WhatsApp:

+86 15711363051

Address:

Xingchuang International C912, Xinya Street No.15, Daxing District, Beijing, China