Graphite Blocks in Electronics:Properties, Applications, and Future Trends

Jan 06,2026

Graphite Blocks in Electronics: A Comprehensive Overview

Table of Contents

- Introduction to Graphite Blocks in Electronics

- Properties of Graphite Blocks

- Manufacturing Process of Graphite Blocks

- Applications of Graphite Blocks in Electronics

- Advantages of Using Graphite Blocks

- Future Trends in Graphite Blocks

- Environmental Impact of Graphite Production

- FAQ: Graphite Blocks in Electronics

- Conclusion

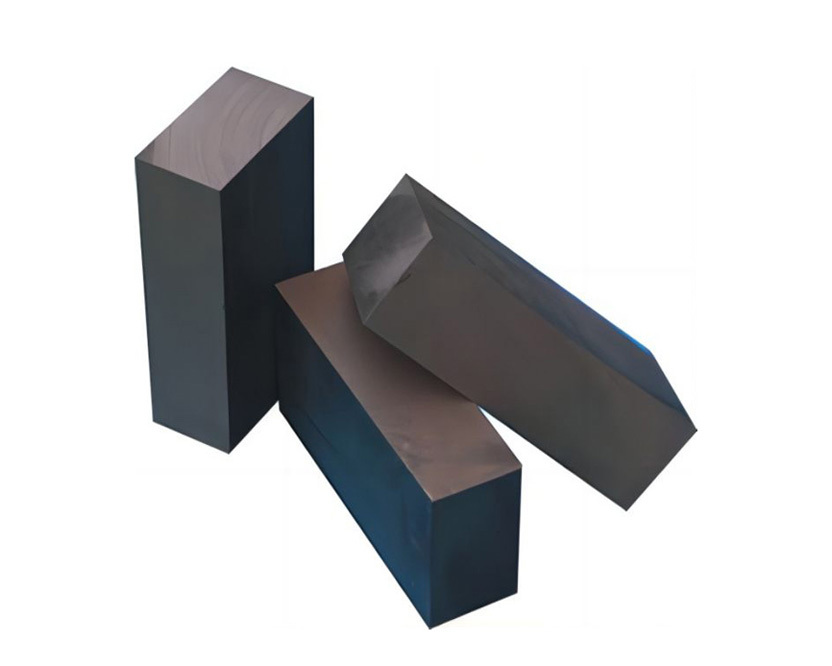

Graphite blocks play a vital role in modern electronics due to their exceptional electrical conductivity, high thermal conductivity, and mechanical strength. From semiconductors to lithium-ion batteries, these graphite blocks for electronics are essential for improving performance, efficiency, and longevity of electronic components.

Introduction to Graphite Blocks in Electronics

As the electronics industry evolves, the demand for high-performance graphite blocks continues to rise. Graphite's unique properties make it an ideal material for applications requiring reliable heat dissipation, electrical conduction, and chemical resistance. Understanding the properties and applications of graphite blocks provides valuable insights for engineers and manufacturers working with electronic graphite materials.

Properties of Graphite Blocks

Graphite blocks are valued in electronics for their combination of electrical, thermal, and mechanical properties:

Electrical Conductivity: Graphite blocks offer excellent electrical conductivity, allowing efficient energy transfer in devices like semiconductors and electrodes.

Thermal Conductivity: Their high thermal conductivity makes them ideal as heat sinks, dissipating heat effectively to prevent overheating.

Mechanical Strength: Graphite blocks are durable, able to withstand high pressures and temperatures without deformation.

Chemical Resistance: Resistant to a wide range of chemicals, ensuring stability and reliability in diverse electronic environments.

Manufacturing Process of Graphite Blocks

The production of graphite blocks for electronics involves several critical steps to ensure high quality:

Raw Material Selection: High-purity natural or synthetic graphite is chosen based on required properties.

Crushing and Milling: Graphite is crushed and milled to uniform size and increased surface area.

Shaping and Molding: Graphite powder is pressed into molds under high pressure to form blocks.

Sintering: The shaped blocks are heated in a controlled environment to enhance density, conductivity, and mechanical strength.

Finishing: Machining or surface finishing ensures precise dimensions and smooth surfaces for electronic applications.

Applications of Graphite Blocks in Electronics

Graphite blocks are widely used across electronic industries:

Semiconductors: Serve as substrates for thin-film growth and high-temperature processes.

Lithium-Ion Batteries: Act as anode materials, facilitating lithium-ion storage and transfer.

Heat Sinks: Provide thermal management in devices, preventing overheating.

Electrodes: Used in fuel cells, electrolysis, and other electrochemical processes.

Insulation Materials: Protect sensitive electronic components from environmental factors.

Advantages of Using Graphite Blocks

Graphite blocks offer several advantages for electronic applications:

Cost-Effectiveness: Abundant and economical compared to alternative materials.

Versatility: Suitable for diverse applications from semiconductors to batteries.

High Performance: Enhances device efficiency, thermal management, and conductivity.

Longevity: Durable material ensures long-lasting electronic components.

Future Trends in Graphite Blocks

The role of graphite blocks in electronics continues to evolve:

Growing Demand for Energy Storage: Electric vehicles and renewable energy systems increase the need for efficient graphite blocks in batteries.

Innovations in Production: Advanced manufacturing methods improve purity, density, and conductivity.

Research and Development: New studies enhance understanding of graphite properties and open new electronic applications.

Environmental Impact of Graphite Production

While graphite is essential for electronics, sustainable production is critical:

Sustainable Sourcing: Natural graphite is sourced responsibly to minimize ecological impact.

Recycling Initiatives: Used graphite blocks can be recycled from electronic components to reduce waste.

Regulatory Compliance: Manufacturers adhere to environmental regulations to ensure eco-friendly production.

FAQ: Graphite Blocks in Electronics

What are graphite blocks used for in electronics?

Semiconductors, batteries, heat sinks, electrodes, and insulation.

How are graphite blocks manufactured?

Through raw material selection, crushing, milling, shaping, sintering, and finishing.

What are the advantages of using graphite blocks?

Cost-effectiveness, versatility, high performance, and longevity.

What is the future outlook for graphite blocks?

Growth in energy storage and production innovations will increase demand.

How does graphite production impact the environment?

Sustainable sourcing, recycling, and regulatory compliance mitigate environmental effects.

Conclusion

Graphite blocks in electronics are indispensable for enhancing performance, efficiency, and durability of electronic components. By understanding their properties, manufacturing process, applications, and environmental impact, engineers and manufacturers can make informed decisions. With rising demand in energy storage and semiconductor technology, high-quality graphite blocks remain crucial for the sustainable growth of the electronics industry.

Contact Us

E-mail:

Phone/WhatsApp:

+86 15711363051

Address:

Xingchuang International C912, Xinya Street No.15, Daxing District, Beijing, China